Need to know more about how OmniDTF works, what accessories it takes, and more? We have an entire Knowledge Base section dedicated to each of our printers. Click the link below to learn more.

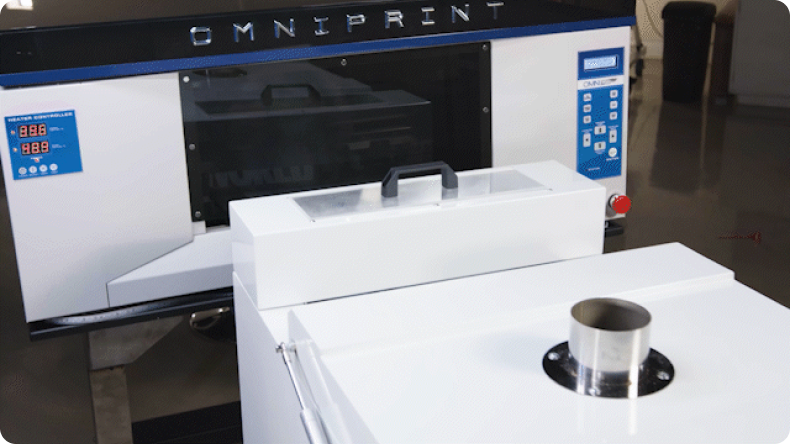

The OmniDTF printing system is a complete direct-to-film (DTF) solution offered by OmniPrint International. It includes a printer, DirectRip software, heat press, and specially formulated DTF inks. This system enables users to print vibrant designs on various fabrics using the DTF transfer method.

DTF printing offers several advantages, including vibrant colors, excellent detail reproduction, and a soft feel on the fabric. It allows for printing on both light and dark-colored garments, providing versatility in design options. Additionally, DTF printing is known for its durability and resistance to fading, ensuring long-lasting prints.

Yes, the OmniDTF printing system is designed to be user-friendly. It includes DirectRip software that simplifies the printing process and optimizes image quality. The printer itself is equipped with advanced features and intuitive controls, making it accessible for both beginners and experienced users.

Yes, the OmniDTF printing system is compatible with a wide range of fabric types, including cotton, polyester, blends, and more. Whether you're printing on t-shirts, hoodies, or other apparel items, the DTF transfer method allows for excellent results on various fabric compositions.

No, the OmniDTF printing system includes all the necessary components for DTF printing. Along with the printer and DirectRip software, it also includes a heat press, which is crucial for transferring the printed film onto the fabric. This provides everything needed to get started with DTF printing.

Get Tips from the Experts

Get Exclusive access to sales